Hot aggregate bin level indicators

Significant cost and energy savings can be made by reducing the amount of hot aggregate waste during coated stone production. However, effectively managing hot stone levels without a visual aid can be difficult. Bin starvation, overflowing material, and excessive cleanouts all increase the fuel costs of production. Our continuous hot aggregate bin level indicators are designed to provide real time, accurate level readings to help you maintain optimum bin levels without creating excessive waste.

Choose from our ED200 level indicator system or the ED200ie individual sensor heads

ED200 Continuous level indicator system for hot aggregate bins - a multi bin installation backed by our 5 year sensor wear guarantee, with centrally housed electronics and PC operator interface, delivering real time, accurate, full height, bin level readings for any shape of bin or density of material.

Features

- Robust sensor channels - gussets in the channel form dead boxes which trap falling stone, so impact is mostly stone on stone which greatly extends the sensor life.

- Bin linearisation - to get an accurate level measurement in non linear bins we fit the sensor channel so it follows the contour of the bin; by doing this we achieve a full height level reading. Our software then applies a linearisation algorithm based on the shape of each bin to produce an accurate linear level reading for the full height of the bin.

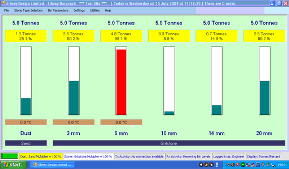

- PC operator interface - our Windows based software is presented on a

net book PC and is intended to

sit alongside the plant VDU, providing the operator with at a glance level readings without the need to switch screens. Up to eight bin levels can be displayed

on one screen. For plants in excess of eight bins a larger TFT display is provided.

- Easy to read bar chart display - each bar is calibrated to the individual bin capacity and has a refresh rate of 100ms to give a smooth real time level reading in tonnes and as a percentage of the bin capacity.

- Multi aggregate calibration feature - the system can be calibrated for up to five different material types with independent settings for dust and sand. This gives a more accurate level reading when switching between materials of different density.

- 4-20mA/0-10v interface - if your PLC or plant control system has the necessary inputs our bin levels can be displayed on the plant VDU.

- Stone temperature readings - fit a set of our temperature probes and this additional information will help reduce the waste associated with cleaning out material which has been left sitting in the bin during breaks in production.

- Safe to weld isolator - flip one switch and the indicator electronics are isolated to prevent damage during maintenance.

- 5 year sensor wear guarantee - our sensor channels and isolating pillars are designed to withstand extreme temperatures and the constant wear from highly abrasive stone, so we can confidently offer a 5 year wear guarantee. Our experience over the years has been that the sensor channels and pillars have an average life in the region of 7 years, even in the hardest of stone, we are confident you will have many years of maintenance free operation.

|

ED200ie Individual hot aggregate sensor heads for continuous level measurement - designed to be connected to existing bin metal work or metal work of your choice, these heads give you the flexibility to build a system around your specific needs and budget. They can easily be interfaced to an existing plant control system or PLC (providing you have the necessary inputs), or for a more advanced set of level measurement features they can be connected to our operator interface. |

|

|

Features:

Connect to the Ellway Design operator interface for bin linearisation and multi aggregate calibration. |

|

|

Hot aggregate temperature sensors - complete your level indicator installation with a set of temperature probes, connected to a digital display or a directly to the plant control system, to help your operator achieve the optimal stone temperature. Power input: 110v or 230v ac 0.5A Output: 4-20mA signal |

|

ED102 point level indicator - our most robust point level indicator, purpose built for use in dry aggregates and abrasive powders. We recommend this indicator for use in the baghouse. if you only operate the discharge mechanism on demand this indicator together with our alarm unit is ideal for providing a high level warning when the collection hopper is full. A continuous level reading can also be obtained by installing a single ED200 sensor channel and bar chart readout. Probe: 1m standard - longer or shorter lengths available to order Power input: 110v or 230v ac 0.5A Output: ED109 alarm unit or one volt free change over contact rated 230v 1A Push button sensor testing: Our alarm units incorporate a test push button which applies an input to the sensor head to simulate a high level, so that the electronics in the sensor head and the audible and visual warnings can be tested prior to filling. Optional items:

|

|